About Authors:

Amit A. Patel

Seth G. L. Bihani S.D. College of Technical Education,

Institute of Pharmaceutical Sciences and Drug Research,

Sri Ganganagar, Rajasthan, INDIA.

amitpatelmx@gmail.com

ABSTRACT:

Quality is critical in achieving competitiveness in domestic and global market. Quality is a journey starting from design, to conformance, and ends at better performance. This process considers quality as a ‘never ending’ improvement. The success of TQM mainly depends on the achievement of internal as well as external customer satisfaction. Internal customer satisfaction is a prerequisite to achieve external customer satisfaction.

If Employees are to identify and correct quality problems, then they have to use some quality tools. Quality circles are also known as work improvement or quality teams. the quality circle is a small group of employees who voluntarily meet at regular times to identify, analyse and solve quality and other problems in their working environment.

[adsense:336x280:8701650588]

Reference Id: PHARMATUTOR-ART-1553

1. INTRODUCTION

In the present competitive environment, survival of the organizations depends on their ability to continuously improve as per the expectations of the customers. Quality is critical in achieving competitiveness in domestic and global market.

Though there are wide variety of concepts surrounding the term “quality”, all writers agree that quality is one of the important “critical success factors” to achieve competitiveness in organizations. Quality has expanded beyond the concept of “customer satisfaction with products and services” to the concept of “creation of worth for all stakeholders”.

In this context, overall business excellence is replacing the narrow objective of meeting customer specifications to improving the performance of the whole system. This includes array of issues, including environment, occupational health and safety, and social responsibility.6

The success of TQM mainly depends on the achievement of internal as well as external customer satisfaction. Internal customer satisfaction is a prerequisite to achieve external customer satisfaction.

Quality is a journey starting from design, to conformance, and ends at better performance. This process considers quality as a ‘never ending’ improvement (Gitlow, 1989).

Quality of design → conformance → performance

a. Quality of design: This is the degree of achievement of purpose by the design itself. It starts with market research, sales feedback analysis and continues the development of a product/service that would satisfy the customer.

b. Quality of conformance: It is the extent to which a firm, its processes and its suppliers are able to surpass the design specifications required to serve the needs of the customer.

c. Quality of performance: This identifies the extent to which customer needs are satisfied by performance of a product/service over a period of time.6

Total - The responsibility for achieving Quality rests with everyone a business no matter what their function. It recognises the necessity to develop processes across the business, that together lead to the reliable delivery of exact, agreed customer requirements. This will achieve the most competitive cost position and a higher return on investment.

Quality - The prime task of any business is to understand the needs of the customer, then deliver the product or service at the agreed time, place and price, on every occasion. This will retain current customers, assist in acquiring new ones and lead to a subsequent increase in market share.

Management - Top management lead the drive to achieve quality for customers, by communicating the business vision and values to all employees; ensuring the right business processes are in place; introducing and maintaining a continuous improvement culture. To gain an understanding of TQM, it is worth looking at how it developed and the impact of some of the main management "gurus" over the years.3

2. DEFINiTION OF TOTAL QUALITY MANAGEMENT

Total quality management is a business philosophy that seeks to encourage both individual and collective responsibility to quality at every stage of the production process from initial design and conception through to after sales services.

TQM is a management philosophy, a paradigm, a continuous improvement approach to doing business through a new management model. The TQM philosophy evolved from the continuous improvement philosophy with a focus on quality as the main dimension of business.

TQM is a comprehensive management system which:

♦ Focuses on meeting owners’/customers’ needs by providing quality services at a cost that provides value to the owners/customers

♦ Is driven by the quest for continuous improvement in all operations

♦ Recognizes that everyone in the organization has owners/customers who are either internal or external

♦ Views an organization as an internal system with a common aim rather than as individual departments acting to maximize their own performances

♦ Focuses on the way tasks are accomplished rather than simply what tasks are accomplished

♦ Emphasizes teamwork and a high level of participation by all employees.6

3. CONCEPTS FROM QUALITY GURUS

(a) Deming’s approach.

Deming had made a highly significant contribution during the war in increasing America's industrial efficiency.

After the war was won, although well received by engineers and scientists, top management did not respond to his ideas. Industry went back to the old established ways of trying to meet consumer market opportunities.

In Japan however Deming found a much more receptive audience, his ideas once implemented led during the 80s, to American business being battered by Japan's superior industrial practices.

In order to compete and survive, the rest of the world were forced to take his ideas seriously, adopting "Japanese methods" such as TQM and Lean Manufacturing.

Deming proposed 14 points as the principles of TQM (Deming, 1986), which are listed below:

PRINCIPLE 1: "Create a constancy of purpose"

· Define the problems of today and the future

· Allocate resources for long-term planning

· Allocate resources for research and education

· Constantly improve design of product and service

PRINCIPLE 2: "Adopt the new philosophy"

· Quality costs less not more

· Superstitious learning

· The call for major change

· Stop looking at your competition and look at your customer instead

PRINCIPLE 3: "Cease dependence on inspection"

· Quality does not come from inspection

· Mass inspection is unreliable, costly, and ineffective

· Inspectors fail to agree with each other

· Inspection should be used to collect data for process control

PRINCIPLE 4: "Do not award business basedon price tag alone"

· Price alone has no meaning

· Change focus from lowest initial cost to lowest total cost

· Work toward a single source and long term relationship

· Establish a mutual confidence and aid between purchaser and vendor

PRINCIPLE 5 : "Improve constantly the system of production and service"

· Quality starts with the intent of management

· Teamwork in design is fundamental

· Forever, continue to reduce waste and continue to improve

· Putting out fires is not improvement of the process

PRINCIPLE 6 : "Institute training"

· Management must provide the setting where workers can be successful

· Management must remove the inhibitors to good work

· Management needs an appreciation of variation

· This is management's new role.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

PRINCIPLE 7: "Adopt and institute leadership"

· MBO's

· Work standards

· Meet specifications

· Zero defects

· Appraisal of performance

· Replace with leadership

Leaders must:

· Remove barriers to pride of workmanship

· Know the work they supervise

· Know the difference between special and common cause of variation

PRINCIPLE 8 : "Drive out fear"

· The common denominator of fear

· The fear of knowledge

· Performance appraisals

· Management by fear or numbers

PRINCIPLE 9: "Break barriers among staff areas"

· Know your internal suppliers and customers

· Promote team work

PRINCIPLE 10: "Eliminate slogans, exhortations,and targets

· They are directed at the wrong group

· They generate frustration and resentment

· Use posters that explain what management is doing to improve the work environment

PRINCIPLE 11:"Eliminate numerical quotas"

· They impede quality

· They reduce production

· A person's job becomes meeting a quota

PRINCIPLE 12 : "Remove barriers"

· Performance appraisal systems

· Production rates

· Financial management systems

· Allow people to take pride in their workmanship

PRINCIPLE 13:"Institute a program of education and self-improvement"

· Commitment to lifelong employment

· Overtime and education

· Work with higher education of needs

· Develop team building skills in children

PRINCIPLE 14: "Take action to accomplish the transformation" Management must:

· Struggle over the fourteen points

· Take pride in the new philosophy

· Include the critical mass of people in the change

· Learn and use the Shewhart cycle2

(b) Juran’s approach :

Juran believed that main quality problems are due to management rather than workers. The attainment of quality requires activities in all functions of a firm. Firm-wide assessment of quality, supplier quality management, using statistical methods, quality information system, and competitive benchmarking are essential to quality improvement. Juran’s approach is emphasis on team (QC circles and self-managing teams) and project work, which can promote quality improvement, improve communication between management and employees coordination, and improve coordination between employees.

According to Juran, it is very important to understand customer needs. Identifying customer needs requires more vigorous analysis and understanding to ensure the product meets customers’ needs and is fit for its intended use, not just meeting product specifications. Thus, market research is essential for identifying customers’ needs.

Juran considered quality management as three basic processes (Juran Trilogy): Quality control, quality improvement, and quality planning.

Juran defined four broad categories of quality costs, which can be used to evaluate the firm’s costs related to quality. Such information is valuable to quality improvement. The four quality costs are listed as follows:

- Internal failure costs (scrap, rework, failure analysis, etc.), associated with defects found prior to transfer of the product to the customer;

- External failure costs (warranty charges, complaint adjustment, returned material, allowances, etc.), associated with defects found after product is shipped to the customer;

- Appraisal costs (incoming, in-process, and final inspection and testing, product quality audits, maintaining accuracy of testing equipment, etc.), incurred in determining the degree of conformance to quality requirements;

- Prevention costs (quality planning, new product review, quality audits, supplier quality evaluation, training, etc.), incurred in keeping failure and appraisal costs to a minimum.2

(c).Crosby’s Approach:

Crosby (1979) identified a number of important principles and practices for a successful quality improvement program, which include, for example, management participation, management responsibility for quality, employee recognition, education, reduction of the cost of quality (prevention costs, appraisal costs, and failure costs), emphasis on prevention rather than after-the-event inspection, doing things right the first time, and zero defects.

Crosby offered a 14-step program that can guide firms in pursuing quality improvement. These steps are listed as follows:

(1) Management commitment: To make it clear where management stands on quality.

(2) Quality improvement team: To run the quality improvement program.

(3) Quality measurement: To provide a display of current and potential nonconformance problems in a manner that permits objective evaluation and corrective action.

(4) Cost of quality: To define the ingredients of the cost of quality, and explain its use as a management tool.

(5) Quality awareness: To provide a method of raising the personal concern felt by all personnel in the company toward the conformance of the product or service and the quality reputation of the company.

(6) Corrective action: To provide a systematic method of resolving forever the problems that are identical through previous action steps.

(7) Zero defects planning: To investigate the various activities that must be conducted in preparation for formally launching the Zero Defects program.

(8) Supervisor training: To define the type of training that supervisors need in order to actively carry out their part of the quality improvement program.

(9) Zero defects day: To create an event that will make all employees realize, through a personal experience, that there has been a change.

(10) Goal setting: To turn pledges and commitment into actions by encouraging individuals to establish improvement goals for themselves and their groups.

(11) Error causal removal: To give the individual employee a method of communicating to management the situation that makes it difficult for the employee to meet the pledge to improve.

(12) Recognition: To appreciate those who participate.

(13) Quality councils: To bring together the professional quality people for planned communication on a regular basis.

(14) Do it over again: To emphasize that the quality improvement program never ends.2

(d). Ishikawa’s Approach:

Ishikawa6 (1985) argued that quality management extends beyond the product and encompasses after-sales service, the quality of management, the quality of individuals and the firm itself. He claimed that the success of a firm is highly dependent on treating quality improvement as a never-ending quest. A commitment to continuous improvement can ensure that people will never stop learning. He advocated employee participation as the key to the successful implementation of TQM. Quality circles, he believed, are an important vehicle to achieve this. Like all other gurus he emphasized the importance of education, stating that quality begins and ends with it. He has been associated with the development and advocacy of universal education in the seven QC tools (Ishikawa, 1985). These tools are listed below:

- Pareto chart;

- Cause and effect diagram (Ishikawa diagram);

- Stratification chart;

- Scatter diagram;

- Check sheet;

- Histogram;

-Control chart.

Ishikawa’s concept of TQM contains the following six fundamental principles:

- Quality first-not short-term profits first;

- Customer orientation-not producer orientation;

- The next step is your customer-breaking down the barrier of sectionalism;

- Using facts and data to make presentations-utilization of statistical methods;

- Respect for humanity as a management philosophy, full participatory management;

- Cross-functional management.2

4. ELEMENTS OF T.Q.M.

These elements can be divided into four groups according to their function.

Foundation – it includes: ethics, integrity and trust.

Building bricks – it includes: Training, teamwork and leadership.

Binding mortar – it includes: communication.

Roof – it includes recognition

TQM has been coined to describe a philosophy that makes quality the driving force behind Leadership, design, planning, and improvement initiatives.

I. Foundation

1. Ethics

Ethics is discipline concerned with good and bad in any situation. It is two faceted subject represented by organization and individual ethics.

Organization ethics establish a business code of ethics that outlines guidelines that all employees are to adhere to in the performance of their work.

Individual ethics include personal rights or wrongs.

2. Integrity

Integrity implies honest , morals, values, fairness, and adherence to the fact and sincerity. The characteristics is what customer ( internal or external ) expect and deserve to receive. Peoples see the opposite of integrity as duplicity. TQM will not work in an atmosphere of duplicity.

3. Trust

Trust is by- products of integrity and ethical conduct. Without trust , the framework of TQM can not be built. Trust forester full participation of all members. It allows empowerment that encourage pride ownership and it encourage commitment.4

II. Bricks

Basing on the strong foundation of the trust, ethics and integrity, bricks are placed to reach the roof of recognition it includes;

4. Training

Training is very important for employees to be highly productive. Supervisors are solely responsible for implementing TQM within their departments and teaching their employee and philosophy of TQM.

Training that employees require are interpersonal skills, the ability to fuction within terns problem solving, decision making, job management, performance analysis and improvement, business economics and technical skills.

5. Teamwork

To become successful in the business, teamwork is also key element of TQM. With the use of teams, the business will receive quicker and better solution to problems. Teams also provide more permanent improvement in processes and operations.

There are mainly three type of teams that TQM organization adopt:

A. Quality improvement teams or excellence teams ( QITS )

These are temporary team with the purpose of dealing with specific problems that often re-occur. These team are set up for period of three to twelve months.

B. Problem solving teams ( PST )

These are teamporary teams to solve certain problems and also to identity and overcome cause of problems. They generally last from one week to three months.

C. Natural work teams (NWT )

These teams consists of small groups of skilled workers who share task and responsibilities. These use concept such as employee involvement teams, self-managing teams and circles. these teams generally works for one to two hours a week.

6. Leadership

It is possibly the most important element in TQM. It appears everywhere in an organization. Leadership in TQM requires the manager to provide an inspiring vision, make strategic direction that are understood by all and to instill value that guide subordinates.

For TQM to be successful in the business, the supervisor must be committed in leading his employees. A supervisor must understand TQM, believe in it and then demonstrate their believe and commitment through their daily practices of TQM.4

III. Binding mortar

7. Communication

It binds everything together. Starting from to roof the TQM house, everything is bound by strong mortar of communication. It acts as a vital linkbetween all elements of TQM. Communication means a common understanding of ideas between the sender and the receiver.

The success of TQM demands communication with and among all the organization members, supplier and customers. Supervisor must keep open airway where employee can send and receive information about the TQM process.

There are different ways of communication such as:

A. Downward communication – this is dominants form of communication in an organization. Presentation and discussion basically do it. By this the supervisor are able to make the employees clear about TQM.

B. Upward communication – by this lower level of employees are to provide suggestion to upper management of the effects of TQM. As employees provide insight and constructive criticism, supervisors must listen effectively to correct the situation that comes about through the use of TQM. This forms a level of trust between supervisors and employees.

C. Sideways communication – this type of communication is important because it breaks down barrier between departments. It also allows dealing with customers and suppliers in a more professional manner.4

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

IV. Roof

8. Recognization –

It is the lastand final element in the entire system it shoud be provided for both suggestions and achievements for teams as well as individuals. Employees strive to receive recognition for themselves and their teams.

Detecting and recognizing contributors is the most important job a supervisor. As people are recognized, there can be huge changes in self-esteem, productivity , quality and the amount if effort exhorted to the task at hand. Recognition comes in its form when it is immediately following an action that an employee has performed.

Recognition comes in different ways, places and time such as, ways-

It can be by way of personal letter from top management.

Also by award banquets, plaques, trophies etc.

Places- good performers can be recognized in front of departments, on performance boards and also in front of top management.

Time - recognition given at any time like in staff meeting, annual award banquets, etc.

We can conclude that these eight elements are key in ensuring the success of TQM.

In an organization and that the supervisor is a huge part in developing these elements in the work place. without these elements, the business entities can not be successful TQM implementers.

It is very clear from the above that TQM without involving integrity, ethics and trust would be great remiss, in fact it would be incomplete.

Training is the key by which the organization creates a TQM environment.

Leadership and teamwork go hand in hand.

Lack of communication between departments, supervisors and employees create a burden on the whole TQM process.

Last but not least, recognition should be given to people who contributed to the overall completed task.

Hence, lead by example, train employees to provide a quality product, creats an environment where there is no fear to share knowledge, and credit where credit is due.

The primary elements in the Deming Application Prize and the checklist used to evaluate senior executives are listed below:

(1) Policies

- Quality and quality control policies and their place in overall business management;

- Clarity of policies (targets and priority measures);

- Methods and processes for establishing policies;

- Relationship of policies to long- and short-term plans;

- Communication (deployment) of policies, and grasp and management of achieving policies;

- Executives’ and managers’ leadership.

(2) Organization

- Appropriateness of the organizational structure for quality control and status of employee involvement;

- Clarity of authority and responsibility;

- Status of interdepartmental coordination;

- Status of committee and project team activities;

- Status of staff activities;

- Relationships with associated companies (group companies, vendors, contractors, sales companies, etc.).

(3) Information

- Appropriateness of collecting and communicating external information;

- Appropriateness of collecting and communicating internal information;

- Status of applying statistical techniques to data analysis;

- Appropriateness of information retention;

- Status of utilizing information;

- Status of utilizing computers for data processing.

(4) Standardization

- Appropriateness of the system of standards;

- Procedures for establishing, revising and abolishing standards;

- Actual performance in establishing, revising and abolishing standards;

- Contents of standards;

- Status of utilizing and adhering to standards;

- Status of systematically developing, accumulating, handing down and utilizing technologies.

(5) Human resources

- Education and training plans and their development and results utilization;

- Status of quality consciousness, consciousness of managing jobs, and understanding of quality control;

- Status of supporting and motivating self-development and self-realization;

- Status of understanding and utilizing statistical concepts and methods;

- Status of QC circle development and improvement suggestions;

- Status of supporting the development of human resources in associated companies.

(6) Quality assurance

- Status of managing the quality assurance activities system;

- Status of quality control diagnosis;

- Status of new product and technology development (including quality analysis, quality deployment and design review activities);

- Status of process control;

- Status of process analysis and process improvement (including process capability studies);

- Status of inspection, quality evaluation and quality audit;

- Status of managing production equipment, measuring instruments and vendors;

- Status of packaging, storage, transportation, sales and service activities;

- Grasping and responding to product usage, disposal, recovery and recycling;

- Status of quality assurance;

- Grasping of the status of customer satisfaction;

- Status of assuring reliability, safety, product liability and environmental protection.

(7) Maintenance

- Rotation of management (PDCA) cycle control activities;

- Methods for determining control items and their levels;

- In-control situations (status of utilizing control charts and other tools);

- Status of taking temporary and permanent measures;

- Status of operating management systems for cost, quantity, delivery, etc.;

- Relationship of quality assurance system to other operating management systems.

(8) Improvement

- Methods of selecting themes (important activities, problems and priority issues);

- Linkage of analytical methods and intrinsic technology;

- Status of utilizing statistical methods for analysis;

- Utilization of analysis results;

- Status of confirming improvement results and transferring them to maintenance/control activities;

- Contribution of QC circle activities.

(9) Effects

- Tangible effects (such as quality, delivery, cost, profit, safety and environment);

- Intangible effects;

- Methods for measuring and grasping effects;

- Customer satisfaction and employee satisfaction;

- Influence on associated companies;

- Influence on local and international communities.

(l0) Future plans

- Status of grasping current situations;

- Future plans for improving problems;

- Projection of changes in social environment and customer requirements and future plans based on these projected changes;

- Relationships among management philosophy, vision and long-term plans;

- Continuity of quality control activities;

- Concreteness of future plans.4

5. THE PHILOSOPHY OF TQM

What characterizes TQM is the focus on identifying root causes of quality problems and correcting them at the source, as opposed to inspecting the product after it has been made. Not only does TQM encompass the entire organization, but it stresses that quality is customer driven.

(a) quality circle

Some organisations have successfully implemented the use of quality circles as part of an ongoing improvement programme. Others have experimented with quality circles with the best intentions and faced several obstacles, but what is true is that this type of participatory management brings several benefits to all concerned.

Objectives:

1. TO improve the quality and productivity and thus contribute to the improvements and development of the enterprise.

2. To reduce the cost of products or services by waste reduction, safety, effective utilization of resources, avoiding unnecessary errors and defects.

3. To identify and solve work related problems that interferes with production.

4. To tap the creative intelligence of the persons working in the organization and to make full use of the human resources.

5. To permit employees to develop and use greater amount of knowledge and skill and motivate them to apply to a wide range of challenging tasks.

6. To improve communication within the organization.

7. To increase employees loyalty and commitment to the organization and its goals.

8. To respect humanity and build a happy bright work place environment which is meaningful to work in.

9. To enrich human capability, confidence, moral, attitude and relationship.

10. To safety the human needs of recognition , achievement and self-development.

Advantage:

1. Promote high level of productivity and quality-mindedness.

2. Self and mutual development of employees.

3. Creating team spirit and unity of action.

4. Increased motivation, job satisfaction and pride in their work.

5. Reduced absenteeism and labour turnover.

6. Developing sense of belongingness towards a particular organization.

7. Waste reduction.

8. Cost reduction.

9. Improved communication.

10. Safety improvement.

11. Increase utilization of human resource potential.

12. Enhancement in consciousness and moral of employees through re cognition of their activities.

13. Leadership development.

14. Trained staff.7

Function of quality circle:

Quality circles are also commonly known as work improvement or quality teams, but no matter the name, their functions share similar characteristics. Generally, the quality circle is a small group of employees who voluntarily meet at regular times to identify, analyse and solve quality and other problems in their working environment. Quality circles can recommend and implement improvement strategies and be a useful reservoir for the generation of new ideas.7

Internal Reform Committees (IRC’s):

Internal Reform Committees (IRC’s) are the public service’s tailor-made answer to quality circles. IRC’s were introduced into the public service to encourage full employee participation in home-grown reform initiatives to meet the needs of the public service.

The main objectives were to:

*?Encourage a team culture and team environment;

*?Encourage the flow of new ideas;

*?Improve customer relations and service delivery;

*?Improve levels of communication;

*?Improve operational efficiency; and

*?Create problem prevention attitudes.7

(b)Customer Focus

The first, and overriding, feature of TQM is the company’s focus on its customers.

Quality is defined as meeting or exceeding customer expectations. The goal is to first identify and then meet customer needs. TQM recognizes that a perfectly produced product has little value if it is not what the customer wants. Therefore, we can say that quality is customer driven. However, it is not always easy to determine what the customer wants, because tastes and preferences change. Also, customer expectations often vary from one customer to the next.

There exists in each department, each office, each home, a series of customers, suppliers and customer supplier interfaces. These are “the quality chains”, and they can be broken at any point by one person or one piece of equipment not meeting the requirements of the customer, internal or external. The failure usually finds its way to the interface between the organisation and its external customer, or in the worst case, actually to the external customer.

(c ) Continuous Improvement

Another concept of the TQM philosophy is the focus on continuous improvement. raditional systems operated on the assumption that once a company achieved a certain level of quality, it was successful and needed no further improvements.

Continuous improvement, called kaizen by the Japanese, requires that the company continually strive to be better through learning and problem solving. Because we can never achieve perfection, we must always evaluate our performance and take measures to improve it. Now let’s look at two approaches that can help companies with continuous improvement: the plan –do– study – act (PDSA) cycle and benchmarking.5,1

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

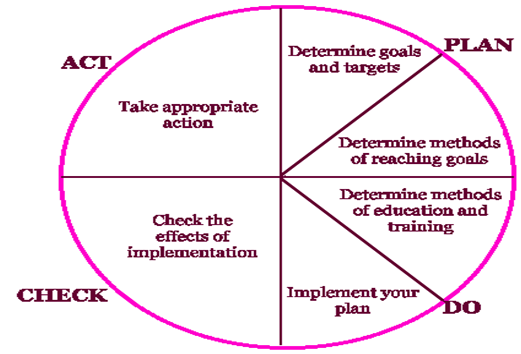

I. The Plan–Do–Study–Act Cycle:

The plan–do–study–act (PDSA) cycle describes the activities a company needs to perform in order to incorporate continuous improvement in its operation.

• PlanThe first step in the PDSA cycle is to plan. Managers must evaluate the current process and make plans based on any problems they find. They need to document all current procedures, collect data, and identify problems. This information should then be studied and used to develop a plan for improvement as well as specific measures to evaluate performance.

• DoThe next step in the cycle is implementing the plan (do). During the implementation process managers should document all changes made and collect data for evaluation.

• Study The third step is to study the data collected in the previous phase. The data are evaluated to see whether the plan is achieving the goals established in the plan phase.

• ActThe last phase of the cycle is to act on the basis of the results of the first three phases. The best way to accomplish this is to communicate the results to other members in the company and then implement the new procedure if it has been successful. Note that this is a cycle; the next step is to plan again. After we have acted, we need to continue evaluating the process, planning, and repeating the cycle again.1,5

II. Benchmarking

SimplyBenchmarking Studying the businesspractices of other companies for purposes of comparison.

Another way companies implement continuous improvement is by studying business practices of companies considered “best in class.” This is called benchmarking. The ability to learn and study how others do things is an important part of continuous improvement. The benchmark company does not have to be in the same business, as long as it excels at something that the company doing the study wishes to emulate.

(d). Quality tools:

You can see that TQM places a great deal of responsibility on all workers. If employees are to identify and correct quality problems, they need proper training. They need to understand how to assess quality by using a variety of quality control tools, how to interpret findings, and how to correct problems. In this section we look at seven different quality tools. These are often called the seven tools of quality control. 1

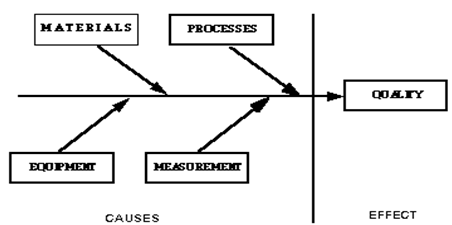

i. Cause-and-Effect Diagrams

Cause-and-effect diagrams are charts that identifypotential causes for particular quality problems. They are often called fishbone diagrams because they look like the bones of a fish.

The “head” of the fish is the quality problem, such as damaged zippers on a garment or broken valves on a tire. The diagram is drawn so that the “spine” of the fish connects the “head” to the possible cause of the problem. These causes could be related to the machines, workers, measure ment, suppliers, materials, and many other aspects of the production process.

Cause-and-effect diagrams are problem-solving tools commonly used by quality control teams. Specific causes of problems can be explored through brainstorming. The development of a cause-and-effect diagram requires the team to think through all the possible causes of poor quality.

ii. Flowcharts

A flowchart is a schematic diagram of the sequence of steps involved in an operation or process. It provides a visual tool that is easy to use and understand. By seeing the steps involved in an operation or process, everyone develops a clear picture of how the operation works and where problems could arise.

iii. Checklists

A checklistis a list of common defects and the number of observed occurrences of these defects. It is a simple yet effective fact-finding tool that allows the worker to collect specific information regarding the defects observed.

if a defect is being observed frequently, a checklist can be developed that measures the number of occurrences per shift, per machine, or per operator. In this fashion we can isolate the location of the particular defect and then focus on correcting the problem.1

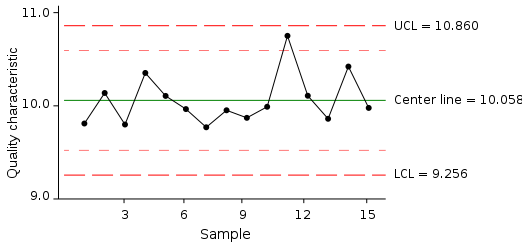

iv. Control Charts

Control charts are a very important quality control tool. These charts are used to evaluate whether a process is operating within expectations relative to some measured value such as weight, width, or volume. For example, we could measure the weight of a sack of flour, the width of a tire, or the volume of a bottle of soft drink. When the production process is operating within expectations, we say that it is “in control.”

To evaluate whether or not a process is in control, we regularly measure the variable of interest and plot it on a control chart. The chart has a line down the center representing the average value of the variable we are measuring. Above and below the center line are two lines, called the upper control limit (UCL) and the lower control limit (LCL). As long as the observed values fall within the upper and lower control limits, the process is in control and there is no problem with quality. When a measured observation falls outside of these limits, there is a problem.

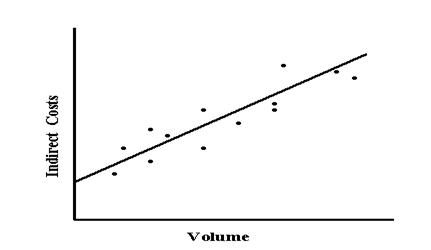

v. Scatter Diagrams

Scatter diagrams are graphs that show how two variables are related to one another. They are particularly useful in detecting the amount of correlation, or the degree of linear relationship, between two variables.

The greater the degree of correlation, the more linear are the observations in the scatter diagram. On the other hand, the more scattered the observations in the diagram, the less correlation exists between the variables.1

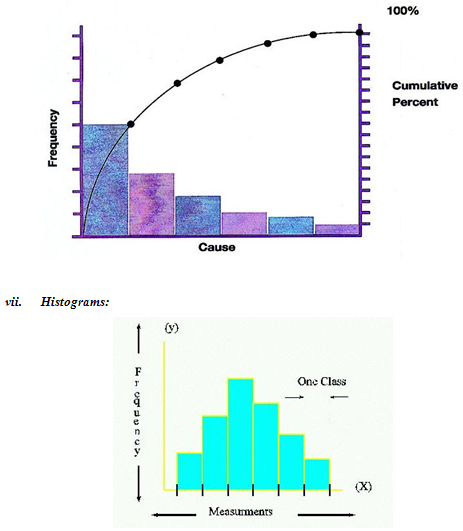

vi. Pareto Analysis

Pareto analysis is a technique used to identify quality problems based on their degree of importance. The logic behind Pareto analysis is that only a few quality problems are important, whereas many others are not critical.

One way to use Pareto analysis is to develop a chart that ranks the causes of poor quality in decreasing order based on the percentage of defects each has caused. For example, a tally can be made of the number of defects that result from different causes, such as operator error, defective parts, or inaccurate machine calibrations,1

vii. Histograms:

A histogram is a chart that shows the frequency distribution of observed values of a variable.We can see from the plot what type of distribution a particular variable displays. such as whether it has a normal distribution and whether the distribution is symmetrical.1

Reference:

1 .” Toatl Quality Management” wiley.com/college/sc/reid/chap5.pdf.

2 . “Concept of Total Quality Management” dissertation.ub.rug.nl/files/faculties/ management/2001/z.zhang/c2.pdf. .

3. “TQM Consultant - Training Article” training management.info/pdf/ TQM%20 training.pdf. .

4. isixsigma.com/index.php?option=com_k2&view=item&id=1333:the-eight-elements-of-tqm&Itemid=179.

5. “Total Quality Management: A Continuous Improvement Process” foundation.phccweb. org/library/article/TQM.pdf. .

6. “Introduction: TQM Basics and Beyond” newagepublishers.com/samplechapter / 001552.pdf.

7. barbados.gov.bb/opsr/docs/quality_circles.pdf .

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE