About Author

About Author

Vinay Kumar Singh.

Head-Formulation

Kumar Organic Products Research Centre Pvt. Ltd., Bengaluru

Pullulan is a linear glucosic polysaccharide produced by the polymorphic fungus Aureobasidium pullulans, which has long been applied for various applications from Pharmaceutical & food additives to environmental remediation agents.

Pullulan possesses some distinct properties such as excellent transparent film–forming ability, moisture absorptivity, water solubility, non-toxicity, and adhesivity. These properties allow pullulan to find potential applications in various industries such as pharmaceuticals, cosmetics, food, and health care.

Origin of pullulan occurred 6-7 decades earlier i.e. in 1950s. Aureobasidium pullulans was first described as Dematium pullulans by De Bary. Bernier was the first to isolate pullulan form Aureobasidium pullulans in 1958. Bender et al studied the novel polysaccharides in1959 and named it pullulan. In 1960s, the basic structure of pullulan was resolved. They discovered the enzyme maltotriose. Thus, pullulan is viewed as α-(1→6) linked polymer of maltotriose subunits. Cately and his coworkers established the occurrence of randomly distributed maltotetraose. pullulanase, which hydrolyses α-(1→6) linkages in pullulan and converts to Pullulan has the safe history of use in Japan as a food ingredient and as pharmaceutical bulking agent. The main use of pullulan has been as a glazing agent having oxygen barrier properties . It has Generally Regarded As Safe (GRAS) status in US for a wide range of applications. Human volunteer studies have only reported the abdominal fullness at doses of 10 g pullulan per day with some mild gastrointestinal symptoms at higher doses. Pullulan is accepted for use as an excipient in pharmaceutical tablets and is listed in the Japanese Standards for Ingredients for drugs. The commercial production of pullulan began in 1976 by the Hayashibra Company, in Okayama, Japan. Pullulan production was an outgrowth of starch syrup production, noted in 1883. Pullulan films were commercialized by Hayashibara in 1982.

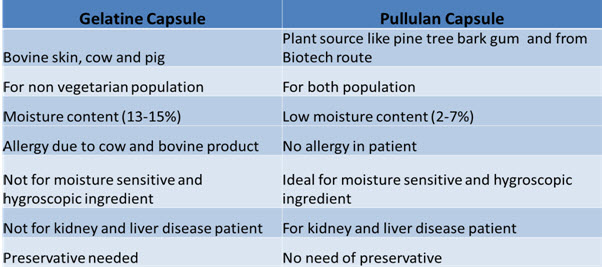

Pullulan Capsules are completely natural vegetable capsules. It is 100% natural and it does not include any identifiable taste. People who are hesitating to take the gelatin can easily take this substitute for their health. In coatings it replaces gelatin. As an edible, mostly tasteless polymer, the chief commercial use of pullulan is in the manufacture of edible films that are used in various breath freshener or oral hygiene products such as Listerine Cool Mint of Johnson and Johnson (USA) and Meltz Super Thin Mints of Avery Bio-Tech Private India Ltd. In the United States, the FDA approved pullulan as safe in 2002. In the European Union, it was recently approved as a food additive (E 1204) for use in capsules, tablets, and films under directive 2006/52/EC. Its use in the food industry is also permitted in several Asian countries, in Russia, and in some South American countries. An advantage of the use of pullulan as a packaging material is its biodegradation, thermal stability, elasticity, and high barrier properties toward oxygen and carbon dioxide.

Moreover, pullulan-based coatings do not have any taste or aroma and are colourless and shiny. Pullulan is a tasteless and odourless white powder. The unique structure of pullulan is responsible for pullulan's high solubility in water and flexibility. The polysaccharide is insoluble in organic solvents, yet highly soluble in water. Solution of pullulan is stable over a wide range of pH and is heat resistant. It is an adhesive when dissolved in water and shows superior adhesiveness on wood compared to corn starch and modified cellulose. Pullulan readily forms a film that is edible, transparent, oil impermeable, and readily soluble in water. The compound is nontoxic, nonmutagenic, noncarcinogenic, biodegradable, and edible. All these exclusive characteristics make pullulan an ideal alternative candidate to petroleum-based polymers. Pullulan dissolves readily in water to form a stable, viscous solution that does not gel. In an atmosphere of a relative humidity of less than 70%, pullulan has an equilibrium moisture content of 10–15% but no hygroscopicity or tackiness. Pullulan resembles gum arabic in viscosity. Its solutions have a surface tension approximating that of water, 74 dyne/cm2. Pullulan solution viscosity is essentially unaffected by pH over a wide range of pH values (< 2 to > 11). It is also relatively heat stable.

Pullulan is stable in the presence of most metal ions.The viscosity shows a sharp increase in the presence of certain ions such as borate that are capable of complexing with hydroxyl groups. Even under such conditions, pullulan does not gel. A significant feature of pullulan is its high stability to sodium chloride. Heating at 100° for 6 hr in 30% sodium chloride effects no noticeable change in viscosity. Pullulan solutions impart high strength to paper or wood and adhere to inorganic substances such as glass, metal and concrete when applied thereon and dried. Pullulan begins thermal decomposition and carbonizes at 250–280°. Pullulan is susceptible to pullulanase and isopullulanase (4-alpha pullulan hydrolase), enzymes that specifically hydrolyze pullulan. Pullulan powder appropriately moistened can be molded by compression molding or extrusion molding while applying heat. Also, pullulan can be spun into fibers or filaments by wet or dry spinning. Films can be made by casting an aqueous pullulan solution on a clean and smooth surface and applying continuous drying. The film dissolves readily in warm or cold water three times faster than does PVA film. It is heat stable and does not lose its flexibility and elasticity even at temperatures of less than 0°.

Pullulan films have a low oxygen permeability of 0.5 cc/m2 • 24 h • atm at 60% relative humidity and 25°. The worldwide market for Pullulan is expected to grow at a CAGR of roughly 2.2% over the next five years, will reach 130 million US$ in 2024, from 120 million US$ in 2019. We at Kumar Organic Products limited manufacture Pollulan having trade name as Kopulan. Kopulan is a 100% natural polysaccharide, produced by the fermentation of cane sugar (non GMO) by Marine Yeast Aureobasidium pullulans. Pullulan is potentially used as pharmaceutical coatings for tablets, pills, and granules because of its high water solubility and low moisture resistance. It also attracts great interest for the uses as predosed formulations wrapping materials for soft and hard capsule.

Pullulan can be formed into capsules. Its excellent oxygen barrier properties ensure that the shelf life of products is optimized. It is non animal origin ensures its suitability for all consumer groups. Its distinct advantage over gelatin capsules is that almost impermeable to oxygen. Thus suitable for encapsulating even oxidation-sensitive ingredients, while there is less need for anti-oxidants. The oxygen barrier properties of pullulan offer 250 times better protection against oxidation than HPMC capsules and 9 times better than gelatin capsules. Because of non – hygroscopic properties of pullulan films, the likelihood of a potential cross linking with encapsulated substances is significantly reduced.

• PULLULAN CAPSULES are especially suitable to protect sensitive neutraceuticals like plant extracts or anti-oxidants and pharmaceutical active ingredients

• Pullulan Tablet coats : When used in a top coat, Pullulan's adhesive properties significantly increases the strength and resilience of the coating reducing damage during transport and distribution.

• Pullulan Oral Strips: Rapid dissolving dosage form (RDDFs) has become increasingly important because of their unique properties. They quickly disintegrate and dissolve, and can be administered without water, making them particularly suitable for pediatrics and geriatric patients.Film formed were transparent, clear, shiny, homogeneous & smooth. Typical strips or films will be between 10-50 mm wide, and 10-50 mm long and weigh 20-100 mg. Maximum dissolution time for Maximum dissolution time for fast dissolving films is 60 sec and thickness 20-70μm.

As Pullulan film is formed, it can be used to entrap flavors, colors and other active ingredients. Due to its excellent oxygen barrier properties these ingredients are effectively stabilized in the film is formed. The film can then be cut to any size. Such technology provides an innovative and ‘easy to use’ carrier and delivery system for a wide variety of ingredients. Furthermore as flavors are sealed in the film matrix such technology provides a means to deliver highly pungent materials which would otherwise need to be segregated.

Pullulan in Tissue engineering and grafting: The surface and the bulk property of any biomaterial is important as it influences the dynamic reactions that take place at tissue implant interface. These properties or the change in the property which can take place over time in-vivo, should be known for designing the biomaterial for specific applications and this can be easily done with pullulan. Na and his co-workers conjugated the pullulan with an interferon-water-soluble low molecular weight recombinant protein which had both anti-viral and immunoregulatory activity. This allowed the user to preserve the biological activity of the drug while enhancing its liver accumulation.Surface modification is an utmost tool for tissue engineering purpose. The surface modification can be easily done with pullulan as it comprises nine hydroxyl groups for substation reactions on the repeating unit.

Applications of pullulan can be enhanced by grafting different chemical groups on it as it contains nine hydroxyl groups, which can be easily substituted. The weight of pullulan increases when grafting is done. The increase in weight of pullulan after grafting clearly indicates the grafting of concerned group on to pullulan.

Pullulan as a carrier for drug delivery : Stimuli-sensitive polymer systems have been used as materials for the delivery of drug. Gheorge et al grafted poly(N-isopropylacrylamide-co-acrylamide) onto the pullulan in order to confer their temperature sensitivity. Then the remaining hydroxyl groups of the pullulan were reacted with succinic anhydride to introduce the pH-sensitive units (-COOH), resulting into the more hydrophilic nature than the native pullulan [43]. Thus, pH-sensitive pullulan microspheres can be prepared for controlled delivery of the drug.

• Liver targeting study focuses on the blood compatibility of the cationic

Liver targeting study focuses on the blood compatibility of the cationic pullulan, physico-chemical characterization, uptake of nanocomplex by hapatocytes and in-vitro transfection. Liver targeting can be achieved by using drug loaded pullulan. Xi and his co-workers studied the liver binding affinity of the modified pullulan in-vitro in hepatocytes and in-vivo in mice.

• Pullulan can be used for tumour cell targeting. Scomparin et al designed

Pullulan can be used for tumour cell targeting. Scomparin et al designed two new anti-cancer polymers for tumour cell targeting. Pullulan was derivatized with either doxorubicin or doxorubicin and folic acid. Then, pullulan was activated by periodate oxidation and functionalized by reductive conjugation cysteamine and 1.9 kDa ammonium polyethyleneglycol [PEG (NH2)]. This study suggests that doxorubicin-pullulan bioconjugates possess suitable properties for passive tumour targeting while folic acid conjugate of pullulan has a limited effect on selective cell uptake.

Application of pullulan to the gene delivery is being explored. Gene therapy using viruses have been performed, but the major drawback of using viruses is that they are immunogenic, disease causing and can be hazardous to health. Pullulan being non-toxic and biocompatible is investigated for gene delivery application. Hosseinkhani et al mixed the pullulan derivative with a plasmid DNA in aqueous solution containing zinc ions to obtain the conjugate of pullulan derivative with plasmid DNA with Zn2+ coordination.

Following are recent advances of pullulan.

Fast disintegrating tablet using pullulan as diluent: Tablet hardess was found to increase without increasing the disintegrating time with high concentration of pullulan.

Pullulan /Silver Nanoparticles composite nanospheres using electrospray techniques for antibacterial application: Controlled spherical structure by controlling the concentration of pullulan, enhanced antibacterial activity Self assembled nanogels of hydrophobized pullulan : Size stability, micelles showed long term colloidal stability with nearly negative neutral charge.

Pullulan acetate coated magnetic nanoparticles for hyperthermia:Nanoparticles have high magnetite content, good biocompatibility, good heating property in magnetic field, and have evident cellular uptake by tumor cells.

Rapid dissolving films of cetirizine hydrochloride using pullulan as a film forming agent: Pullulan acted as rapid film forming agent.

Conclusion :

Pullulan has gained a lot of attention in the past few decades due to its unique properties. Pullulan is an edible bio-polysaccharide with numerous applications in the field of Pharmaceutical industries. The unique property of pullulan is due to its glycosidic linkage. Pullulan is synthesized by fermentation of cane sugar, beet molasses, agro-industrial waste.

Pullulan can be easily derivatized by means of chemical reaction. Pullulan is used as pharmaceutical coatings for tablets, pills, and granules and also used as capsule.Pullulan has important application in the field of biomedical and pharmaceutical field viz., tissue engineering & grafting. Pullulan has been used for liver and tumour target delivery of drug. Pullulan has the application in the field of targeting of drug to liver and cancer cells. Thus Pullulan (Kopulan) has occupied a niche area in Pharmaceutical field.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT admin@pharmatutor.org

FIND OUT MORE ARTICLES AT OUR DATABASE