ABOUT AUTHOR:

Surya Prakash Singh*

Vaagdevi College of Pharmacy,

Dept. of Pharmaceutics, Warangal,

pin:506001, Warangal, A.P, India

surya.prakashsingh@yahoo.com

ABSTRACT:

Nanotechnology, a multi disciplinary science has received considerable attention in the recent times in the discovery of new chemical entities, diagnosis and treatment of several ailments[1]. It has created a remarkable impact on healthcare sector as an offshoot called nanomedicine. Many newer drugs show promising in vitro effect but lack in vivo effect due to decreased bioavailability. Nanomedicine has developed many drug delivering systems like nanoparticles, nanoemulsions, nanosuspensions, nanosponges etc., to overcome the problems of bioavailability out of which nanosponge is an advanced drug delivery system which offers diverse advantages than the other available systems. In this review, an attempt is made to summarize the methods of development, evaluation techniques and possible areas of applications and future of nanosponge drug delivery systems.

REFERENCE ID: PHARMATUTOR-ART-2053

INTRODUCTION

Many drugs face the problem of bioavailability and every year around $65 billion is wasted because of poor bioavailability[2]. Preventing the delivery of a drug at the undesired location is as important as to deliver a drug at a desired location. The main challenges faced by the drug formulator are the bio availability and the side effects. A very potent drug can be fatal, if it is delivered in a wrong region. So a novel drug delivery system is gaining demand in the recent time and huge money is invested in the formulation research and development.

Some of the achievements made using nanomedicine are

· Development of one dose a day ciprofloxacin

· Tumor targeted taxol delivery[3]

· Improved ophthalmic delivery using smart hydrogel nanoparticles[4]

· Oral insulin formulation using nano particles[5]

· Liposomal based Amphotericin B formulation

Nanosponges are innovative carriers consisting of cross linked cyclodextrins able to incorporate molecules within their structures[6]. One can imagine nanosponge, as “a 3D picture of a sponge having cross-linked network of polymers with a pore size in the range of few nanometers”.

The nanosponge is about the size of a virus with a ‘backbone’ (a scaffold structure) of naturally degradable polyester. The long polyester strands are mixed with small molecules that have an affinity for certain portions of the polyester. They ‘cross link’ segments of the polyester to form a spherical shape that has many pockets (or cavities) where drugs can be stored. You might wonder about polyester; this particular version is predictably biodegradable, which means that when it breaks up in the body, the drug contained can be released on a known schedule. Better still the nanosponge can be engineered to be of specific size and to release drugs over time not just in the ‘burst’ mode common with other delivery methods. The engineering capacity of nanosponge is due to the relatively simple chemistry of its polyesters and linking material (peptides); compared to many other nanoscale drug delivery systems, nanosponge should be able to scale (e.g. ramp up to commercial production levels) without requiring unusual equipment or procedures.

figure 1: a model representing the release of nanomed from the formulation

Nanosponge is water soluble. This does not mean the molecules chemically break up in water, but it means that nanosponge particles can mix with water and use it as a transport fluid, for example to be injected. Most other forms of nanoparticle delivery systems must use various chemical transports (for example, adjuvant reagent), which may have side effects. Many authors have described nanosponge in different ways and with different geometry. The efficiency of nanosponge depends on its particle size. Earlier the particle size isexpected to be in the range of 150-400 nm, but most recently the scientists have developed nanosponge with a particle size of 50nm. The size varies depending on the method adopted for formulation.

ADVANTAGES:

1. It can be used as controlled as well as targeted drug delivery system.

2. It offers predictable release of drug which becomes the major advantage when compared to other nanoparticle delivery systems under development.

3. It can also be used for hydrophobic drugs.

4. The solubility of drugs can be increased using nanosponge technology.

5. Method of preparation requires simple chemistry.

METHODS

Three basic methods are employed in the development of nanosponges, each one differs in diverse chemistry from the other. They are

1. Emulsion solvent diffusion method

2. Ultra sonication method

3. Click chemistry

emulsion solvent diffusion method

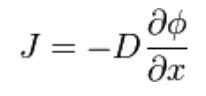

Fick’s first law of diffusion relates, the diffusive flux to concentration, by postulating the flux goes from regions of high concentration to regions of low concentration, with a magnitude that is proportional to the concentration gradient. In one dimension this is

figure2: ficks first law.

Where,

· J is the “diffusion flux” (amount of substance) per unit area per unit time.

· D is the diffusion coefficient or diffusivity.

· ø is the concentration

· x is the position

Using this method nanosponges are prepared by crosslinking the polymers by using a cross linking agents and a volatile solvent[7]. The mixture of drug, polymer and crosslinking agent is added to the solvent being continuously agitated at 1000rpm. The formed nanosponges were filtered and dried in oven at 40?C for 24hrs.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

ultrasonication

Sonication is the act of applying sound (usually ultrasound) energy to agitate particles in a sample for various purposes. In the laboratory[8], it is usually applied using an ultrasonic bath or an ultrasonic probe, colloquially known as a sonicator. Sonication has numerous effects, both chemical and physical. The chemical effects of ultrasound i.e., sonochemistry is concerned with understanding the effect of sonic waves on chemical systems. Sonication is commonly used in nanotechnology for evenly dispersing nanoparticles in a liquid system. Nanosponges are prepared by direct ultrasonication of beta-cyclodextrins and it’s by products with organic carbonates as cross linkers without using solvent. The reaction time usually ranges from 4-5hrs[9].

click chemistry

In the year 2001, Professor Karl Barry Sharpless of the Scripps Research Institute introduced a new chemical philosophy called “Click Chemistry”. It is not a specific reaction but it is a concept that mimics nature[10]. It is used to describe reactions that are high yielding, wide in scope, create only byproducts that can be removed without chromatography, are stereospecific, simple to perform and can be conducted in easily removable or benign solvents.

In biological systems, proteins and sugars are made from polymerization reactions which include several amino acids and monosaccharide units respectively. The connecting units have Carbon-Hetero atom bonds (C-X-C) rather than Carbon-Carbon bonds. Mimicking nature in organic synthesis is essential in the discovery of new pharmaceuticals given the large number of possible structures. Click chemistry in combination with combinatorial chemistry, high-throughput screening and building chemical libraries speeds up new drug discoveries by making each reaction in a multistep synthesis fast, efficient and predictable.

Recently, Eva Harth an assistant Professor of chemistry and pharmacology at Vanderbilt University, USA, has developed ‘nanosponge technology’ by using click chemistry. They used this technique for tailoring the nanoparticle architectures which enabled them to modulate the different release kinetics and can really optimize this targeted drug delivery system for an aggressive cancer for example, or a slower progressing cancer. They got very promising preliminary data on breast, brain and lung cancers with increased efficacy of three to five folds higher than a direct injection of the drug using nanosponge delivery system.

GENERAL EVALUATION

- Particle size: As already said, bioavailabilty depends on particle size therefore it’s very essential to maintain proper particle size of the nanosponge. It is measured using by using AFM (atomic force microscopy) or SEM (scanning electron microscopy). In both the techniques the arial tomography of the particles is obtained and the particle size are measured.

- Polydipersity index: Polydispersity index is a parameter to define the particle size distribution of nanoparticles obtained from photon correlation spectroscopic analysis[11]. It is a dimensionless number extrapolated from the autocorrelation function and ranges from a value of 0.01 for monodispersed particles and upto values of 0.5-0.7. samples with very broad size distribution have polydispersity index values > 0.7.

- Zeta potential: The zeta potential of a particle is the overall charge that the particle acquires in a particular medium and can be measured on “Zetasizer Nano” instrument. The magnitude of the measured zeta potential is an indication of the repulsive force that is present and can be used to predict the long term stability of the product. If all the particles in suspension have a large negative or positive zeta potential then they will tend to repel each other and there is no tendency for the particles to come together. The effect of the pH, concentration of an additive or the ionic strength of the medium on the zeta potential and rheological properties can give information in formulating the nanosponge to give maximum stability.

(Note: Other evaluation criterion varies with the formulation.)

APPLICATIONS

Pharmaceutical:

- It is largely employed in cancer research as a targeted drug delivery system which directly releases the drug at tumor site.

- It can also be employed in the formulation of several antifungal and anti viral drugs which have poor water solubility and low oral bioavailability[12].

- A type of nanosponge has been tested as stationary phase in chromatographic applications to separate metals.

Non pharmaceutical:

1. Nanosponges are employed in the removal of oil spills in oceans which can be reused by treating them with organic solvent like ethanol.

2. Molecular nanosponges are used in ground water purification.

3. Nanosponges are also used in manufacturing of semi conductors.

CONCLUSION AND FUTURE PERSPECTIVES

Nanosponge drug delivery system opens new approaches for delivery of many drugs including water insoluble drugs and for improving efficacy rates. Innovative nanosponge delivery systems are expected to have great effects in the treatment of several lethal diseases. Their role could be important in prevention, early diagnosis, more effective drug delivery systems, specific targeting and personalized therapy. Further it can be used as a platform, not only to deliver small molecule drugs in combinational therapies but also peptides, which are an evolving class of therapeutics. Thus, there is tremendous scope for innovation and availability for patent filing to secure products. Truly, product development using nanosponges, would be rewarding experience

Refrences:

1. Lynn Goldman and Christine Coussens, Roundtable on Environmental Health Sciences, Research and Medicine Implications of Nanotechnology for Environmental Health Research ,2005,38.

2. Ganesh Khamkar*, Rajkumar Moon, Dattatraya Mali, Abhijeet Kale and Rajesh Likhe, Nanomedicine: as a novel application of nanotechnology, Khamkar et al., IJPSR, 2011; Vol. 2(6): 1389-1394.

3. A. T. Singh, M. Jaggi, D. Khattar, A. Awasthi, S. K. Mishra, S. Tyagi, A. C. Burman, A novel nanopolymer based tumor targeted delivery system for paclitaxel , J Clin Oncol 2008; 26: (May 20 suppl; abstr 11095).

4. Saima Amin*, Saeid Rajabnezhad and Kanchan Kohli, Scientific Research and Essay ,2009, Vol. 3 (11), 1175-1183.

5. Bruno Sarmento,1 Susana Martins,1 Domingos Ferreira,1 and Eliana B Souto1,2 ,Oral insulin delivery by means of solid lipid nanoparticles, Int J Nanomedicine. 2007 December; 2(4): 743–749.

6. Marija Bogataj Mateja Cegnar Jelka Dolinar Mirjana Gasperlin Tomaz Vovk, 7th Central European Symposium on Pharmaceutical technology and Biodelivery Systems , Special Issue, September 2008;59.

7. Cohen-Sela E, Chorny M, Koroukhov N, Danenberg HD, Golomb G,A new double emulsion solvent diffusion technique for encapsulating hydrophilic molecules in PLGA nanoparticles,J Control Release,2009,Jan 19;133(2):90-5.

8. Suslick, K. S.; Flannigan, D. J. “Inside a Collapsing Bubble, Sonoluminescence and Conditions during Cavitation” Annual Rev. Phys. Chem. 2008, 59, 659-683.

9. Kirti Deshmukh, Solid Porous Microsphere:Emerging Trend In Pharmaceutical Technology, International Journal Of Pharma And Bio Sciences ,Vol2/Issue1/Jan-Mar 2011

10. H. C. Kolb, M. G. Finn and K. B. Sharpless (2001). Click Chemistry: Diverse Chemical Function from a Few Good Reactions, Angewandte Chemie International Edition 40 (11):2004–2021, PMID 11433435.

11. Kalarical Janardhanan Sreeram Marimuthu Nidhin, Balachandran Unni Nair, Synthesis of aligned hematite nanoparticles on chitosan-alginate films, Colloids and Surface Biointerfaces, 2009,Volume 71, Issue 2 , 260-267.

12. Sushama Talegaonkar*, Adnan Azeem, Farhan J. Ahmad, Roop K. Khar, Shadab A. Pathan and Zeenat I. Khan , Microemulsions: A Novel Approach to Enhanced Drug Delivery, Recent Patents on Drug Delivery & Formulation 2008, 2, 238-257.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE