About Author:

About Author:

Arif Khan,

Malhotra college of pharmacy

Bhopal, MP

RGPV Bhopal, India

Abstract

Document is any written statement or proof of any activity in pharmaceuticals. Documentations are to define the manufacturers system of information & control, to minimize the risk of misinterpretation & errors inherent in oral or casually written communication, to provide unambiguous procedures to be followed to provide confirmation of performance, to allow calculations to be checked & to allow tracing of batch history. Documents are a mirror to show actual image of any pharmaceutical company. Documents and products are produced in pharmaceuticals but regulatory bodies are interested to see documents first. Different documents can describe the different activity in pharma and its actual image. Various documents are producing by pharma company would be discussed below. Due to the importance given to documentation in pharma “good documentation practices” is required. Good documentation is a systematic procedure of preparation, checking, verifying, issuing, storing and reviewing of any documents. Batch record is an important document kept along with reserve sample until one year of expiry of the product, and final products are release only after proper review of BMR, even after testing of Product from QC, product would not be released without review and completing of BMR and other documents .every activity should be available written form as SOPs is a requirements of GMP. Control of document is also an important part of GDP to reduce error and misuses of any documents. Master copy for all activity should be prepared such as SOPs started from Draft copy and finalizes after checking and reviewing and Approved by QA documentation. Final copy should be printed as Master copy and stamped as “master copy” by red ink. A photocopy of master copy should be issued to concern department with stamped “control copy”. A record should be maintained for issuing any documents with sign & date. Every document should have effective date, review date and revision no.

[adsense:336x280:8701650588]

Reference Id: PHARMATUTOR-ART-1288

Introduction

The GDP can be defined as “Good documentation practice is an essential part of the quality assurance and such, related to all aspects of GMP” this definition is based on WHO.

Clearly written documents prevent errors of various activities in pharma each and every activity is written in specific documents such as SOPs and strictly followed. Spoken communications may be create errors so that all important documents such as Master formula record , procedure and record must be free from errors and Documented.

It is difficult to make a list of required documents and totally depend upon Companies activity or environment. Followings are the activity factors considered during designing of any documents.

1. Type of formulation

2. Country requirements

3. Availability of ERP or SAP system

Purpose of Documentations

• Defines specifications and procedures for all materials and methods of manufacture and control

• Ensures all personnel know what to do and when to do it

• Ensure that authorized persons have all information necessary for release of product

• Ensures documented evidence, traceability, provide records and audit trail for investigation

• Ensures availability of data for validation, review and statistical analysis.

Classification of Documentation

[adsense:468x15:2204050025]

Following are the classification of Documents

• For organization & Personnel.

• For Buildings & facilities

• For Equipments.

• For Handling of R.M.& P.M.

• For Production & process control.

• For Packaging & Labeling control.

• For Holding & Distribution

• For Laboratory Control.

• For Records & Reports.

• For Return & Salvaged finished products.

Type of documents used in pharmaceuticals

• Specifications: as per MHRA Specifications describe in detail the requirements with which the products or materials used or obtained during manufacture have to conform. They serve as a basis for quality evaluation. We need specification for:

1. Active and inactive materials

2. Primary printed and packing materials

3. Intermediate and semi finished product

4. Finished product

• SOPs: it is a written, authorized functional instruction used as a reference by the person responsible for performance and are also used for training new operators in the performance of the procedure.

• Test method: it is a written and approved documents describe the detailed testing procedure.

• List: Documents contain a catalog of any object such as list of equipments.

• Certificates of Analysis: it is an authentic documents shows the analytical reports and decision of acceptance/rejections

• Label

• Records

• Organ gram

• Job description

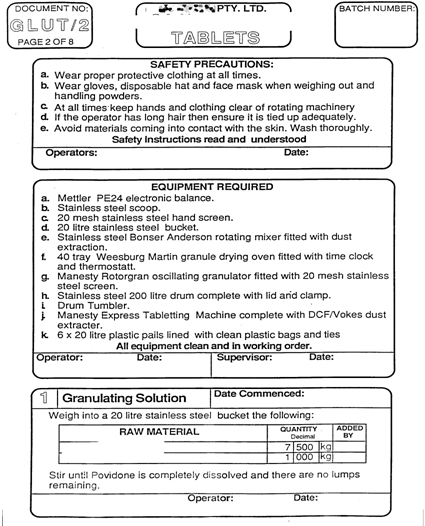

• Batch Manufacturing records: it is an important document issued for every batch of product to assure, review and record keeping of any product batch. There are following major content of BMR.

1. Name of product, generic name, strength, shelf life, manufacturing date and exp date.

1. Name of product, generic name, strength, shelf life, manufacturing date and exp date.

2. A complete list of ingredients with full description, codes and quantity to be issued.

3. A statement for theoretical yield and reconciliation.

4. A complete MFG and control instructions, sampling and testing procedure, specification and precaution to be followed.

5. A statement for processing location and equipment.

6. The method or reference to method to be used for preparing the critical equipment including cleaning, assembling, calibrating and sterilizing.

7. Dates and time of all activities

8. Line clearance procedure in every steps

9. Labeling control and specimen for coding in primary, secondary and tertiary packing materials

10. Deviation record

11. Result of examine made.

Page of BMR

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to PharmaTutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

Site master file: it is a document, which provides all information of a pharmaceutical plant. There are followings content to be needed to prepare a SMF.

1. General information, it includes information related to organization, mfg activities, name and address, type of products description of site employee details external technical support, quality management system.

2. Personnel, organizational chart, Qualification, experience and responsibilities of key personnel Training , health requirements and personnel hygiene clothing

3. Premises and equipments: Description of manufacturing area , nature of construction and finish, brief description of ventilation, special areas, water system, maintenance of premises, major production and laboratory equipments, maintenances of equipments, calibrations and sanitizations.

4. Documents, preparations, revision and distributions of documents,

5. Production, Brief description of production operations, Handling of materials, handling of rejected materials and product, brief description of general policy of process validation.

6. Quality control, quality management system

7. Self inspection, self inspection program.

8. Change control, it is a document for review, approval and implementation of any change in validated system, equipment, process and materials Etc.

9. Protocols: A written plan stating how validation will be conducted and defining acceptance criteria. For example, the protocol for a manufacturing process identifies processing equipment, critical process parameters/operating ranges, product characteristics, sampling, test data to be collected, number of validation runs, and acceptable test results.

Preparation, issues and uses of Documents

Documents should be carefully and logically specify to prevent wrong uses. All necessary information’s are written unambiguously. Each document includes:

1. Company name

2. Purpose and title of documents

3. Identification No and revision No.

4. Date of authorization

5. Date of review

6. Signature of prepared by, checked and authorized by.

7. Distribution list

8. Page no.

9. Reason for revision should be documented.

10. Abbreviation and reference

Each document is clear and computerized so that it is readable, issued documents signed by a concern person to indicate a verified issue. Any correction is made by cutting with single line with signature and date, do not overwrite. Document to filled have a sufficient space, ball ink pen should be used for hand written filling.

Document control

The process by which a manufacturer ensures that all procedures used and documents generated in G.M.P. – related actions are current, accurate and approved.

Purpose of document control to control issuance, possession, use and revision of master documents including

Standard Operating Procedures

Data collection forms

Validation Protocols

Master formulae

Batch records

Function of Quality Assurance Unit

Initially document is prepared by concern department as draft and draft is reviewed by dept. head and final draft is send to QA department that convert a draft to a final documents checked and approved by authorize person. Control copies are issued to concern department and issuance records are maintained. After approval of documents such as sops quality assurance must ensure that all users/concerned department gets training before the implementation of the sops record of such training must be maintained. A training co-coordinator preferably the head of user department or any designated individuals shall be responsible for organizing the training. After successful implementation of training on any sops, the sops become effective.

Original sops are stamped as “MASTER COPY” with red ink, master copy are stored under supervision and photocopy of master copy duly stamped as “CONTROL COPY” in blue color. Sops distribution list should be maintained for issuance records, change in sops need to initiated change request and all issue copies are retrieve and new one implemented with training.

Conclusion:

Implementation of a Good documentation practice for pharmaceutical products will facilitate compliance with GMP and Regulatory bodies. The central goal of a GDP is to define the manufacturers system of information & control, to minimize the risk of misinterpretation & errors inherent in oral or casually written communication, to provide unambiguous procedures to be followed to provide confirmation of performance, to allow calculations to be checked & to allow tracing of batch history and also ensure Quality of products.

References

1.WHO module 12 part-2 January 2006

2.Manohar A potdar ‘pharmaceutical Quality assurance’ Nirali prakashan.

3.www.fda.gov

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to PharmaTutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE